Windows That Generate Energy From The Sun

NEXT Energy Technologies: New Member Spotlight

There are currently only a handful of companies capable of integrating PV within architectural vision glass.

One of the most interesting developments using architectural vision systems comes from ASA’s newest member, NEXT Energy Technologies.

NEXT delivers a product with true transparency and uncompromised aesthetics, designed to match best-selling solar control coatings in terms of color, haze, clarity, visible light transmission, and SHGC.

NEXT produces a transparent photovoltaic technology that transforms window and glass facades into producers of low-cost, on-site renewable energy.

Architectural Solar applications not only bring awareness to sustainability initiatives, but they also increase a building’s energy-generating potential.

Vision glass is an obvious fit for both sustainability and on-site energy generation. But it’s also one of the most challenging applications because it almost always encloses the building envelope. Transparent surfaces are also intrinsically less efficient than opaque surfaces, so they need to be available at lower costs to produce a positive ROI.

NEXT Energy Technology accomplishes this task by integrating their technology into existing glass fabrication processes and leveraging material that’s intrinsically part of the building envelope.

While traditional solar technologies typically add a layer of glass, cells, and encapsulation to the cost of a facade, NEXT’s materials integrate seamlessly on the inside surface of the outboard pane in an insulated glass unit (IGU). Processes that typically deposit low-e coatings can now deposit a coating that has the benefits of low-e while harnessing the sun’s energy—rather than reflecting it.

NEXT’s innovative developments could crack open the BIPV market by integrating with the building industry supply chain and reducing the incremental cost of Architectural Solar (aka BIPV).

NEXT recognizes that it’s unlikely for solar installers to both design and install commercial glazing systems. They offer a product the building industry can trust and integrate into the traditional supply chain. By pursuing licensing agreements with building envelope manufacturers, NEXT’s approach just might make solar vision glass ubiquitous.

In 2017, NEXT executed their first joint development and license agreement with a top U.S. commercial window fabricator and are currently in active discussions with additional organizations in Asia and Europe.

NEXT is also in the process of demonstrating pilot production and is targeting market entry in the U.S., Europe, and Japan within the next two years. Europe and Japan have Net Zero regulations that take effect in 2020, which is a huge driver for NEXT’s global photovoltaic strategy.

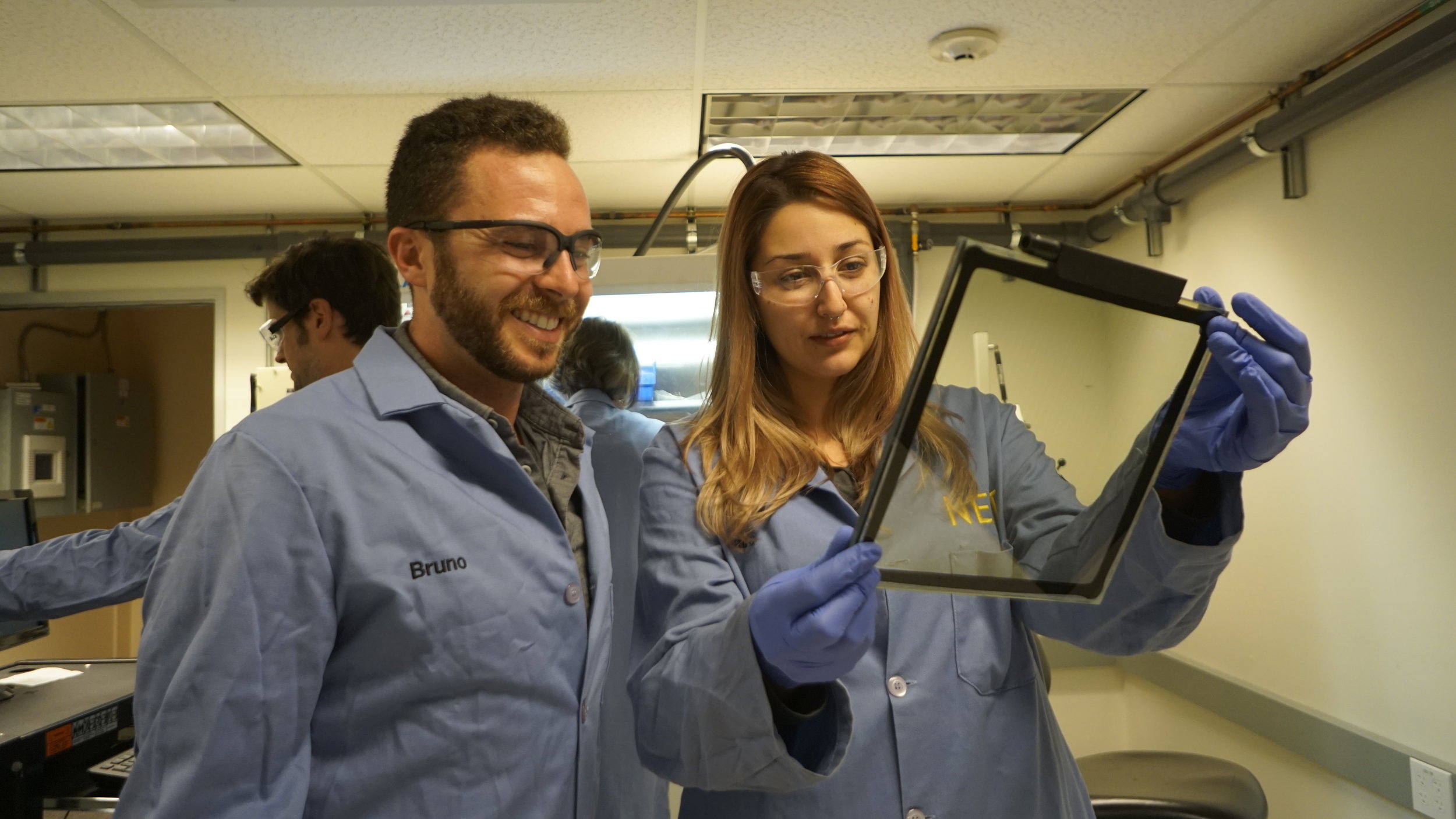

NEXT's Engineers assess a functional prototype in its Santa Barbara, CA lab.

Some may argue that vertical surfaces capture far less energy than more optimal orientations. But at the end of the day, there’s a drive within the architectural community to offset as much of a building’s load as possible.

Transparent vertical glass surfaces are analogous to energy-hungry structures. Commercial buildings with a high wall-to-roof ratio may require PV integration on these surfaces to achieve a net-zero or nearly net-zero construction goal.

NEXT's proprietary organic semiconducting dyes are printed directly onto architectural glass and integrated into photovoltaic insulated glass units.

NEXT’s breakthrough PV technology offers low-e performance in a range of colors with the benefit of energy generation. Their organic semiconductor technology has exceptional low light and high angle performance, which is ideal for vertical applications.

Additionally, the integration of NEXT’s PV coating into a dual pane window eliminates the need for encapsulation. Perhaps the most important feature is that their technology is based on a scalable printing method that can be easily implemented into existing glass fabrication processes.

For more on NEXT, check out this interview with Jeff Horowitz, the company’s director of business development and partnerships, where he discusses the benefits of their technology.

NEXT’s Co-Founder and CTO, Dr. Corey Hoven, was also recently featured in Forbes’ online publication.

We’re so excited to have NEXT on board the ASA movement and look forward to following their success as they revolutionize the vision glass industry.

To learn more about becoming an ASA member, check this out.